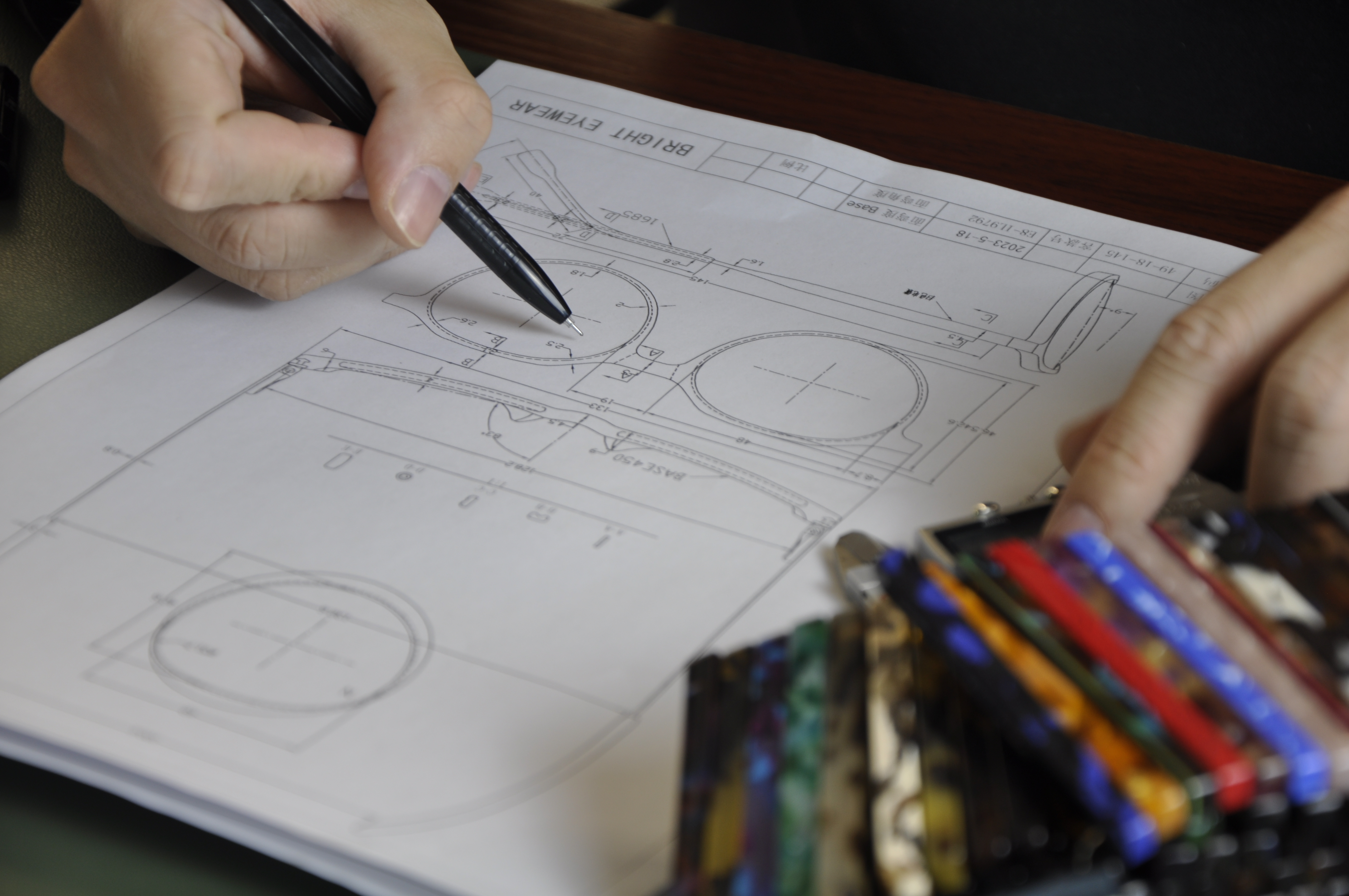

A Complete Guide to Sunglass Lens Materials: How to Choose the Right One for Your Brand

May 09, 2025

When it comes to building a successful sunglasses brand, choosing the right lens material is just as critical as frame design or branding. The right lens not only enhances optical performance, but also aligns with your product positioning — whether it's for fashion, sports, or high-end luxury.

In this guide, we’ll help you understand the most commonly used sunglass lens materials in the eyewear manufacturing industry, and how to choose the right one for your brand.

🔍 Key Sunglass Lens Materials Explained

Here are the five most widely used lens materials in B2B sunglasses production — each with its own characteristics, applications, and price tier.

🟠 TAC (Tri-Acetate Cellulose) – Polarized and Budget-Friendly

-

Polarized: ✔ Yes (inherently polarized)

-

Standard Thickness: 0.74mm or 1.1mm

-

Hardness: C

-

Elasticity: A

-

Price Level: C (affordable)

-

Typical Uses:

-

Sports sunglasses

-

Cycling glasses, fishing sunglasses, and outdoor performance wear

-

Pros:

-

Lightweight

-

High polarization at low cost

-

Flexible for mass-market designs

Cons:

-

Low scratch resistance

👉 Best for brands targeting the sports or activewear market with cost-effective polarized options.

🟡 CR-39 (Resin) – Balanced Optical Clarity for Fashion Lines

-

Polarized: ✳ Optional (can be made polarized)

-

Standard Thickness: 2.0mm

-

Hardness: B

-

Elasticity: C

-

Price Level: B (mid-range)

-

Typical Uses:

-

Fashion-focused sunglasses

-

Private label collections for lifestyle brands

-

Pros:

-

Good optical clarity

-

Scratch resistance better than TAC

-

Cost-effective for premium mass production

Cons:

-

Slightly heavier than nylon

-

Less impact resistance

👉 Ideal for brands focused on fashion aesthetics — a perfect balance between quality and affordability.

🔵 Nylon – Flexible, Durable, and Great for Special Designs

-

Polarized: ✳ Optional (can be made polarized)

-

Standard Thickness: Around 2.0mm

-

Hardness: B

-

Elasticity: B

-

Price Level: B (mid-range)

-

Typical Uses:

-

Sports eyewear

-

Performance sunglasses with drilled lenses or unique shapes

-

Pros:

-

Excellent flexibility and impact resistance

-

Very lightweight

-

Suitable for drilled lenses and wrap-around shapes

Cons:

-

Less scratch-resistant

-

Not inherently polarized

👉 Perfect for brands developing high-performance or uniquely shaped eyewear — such as rimless or curved designs.

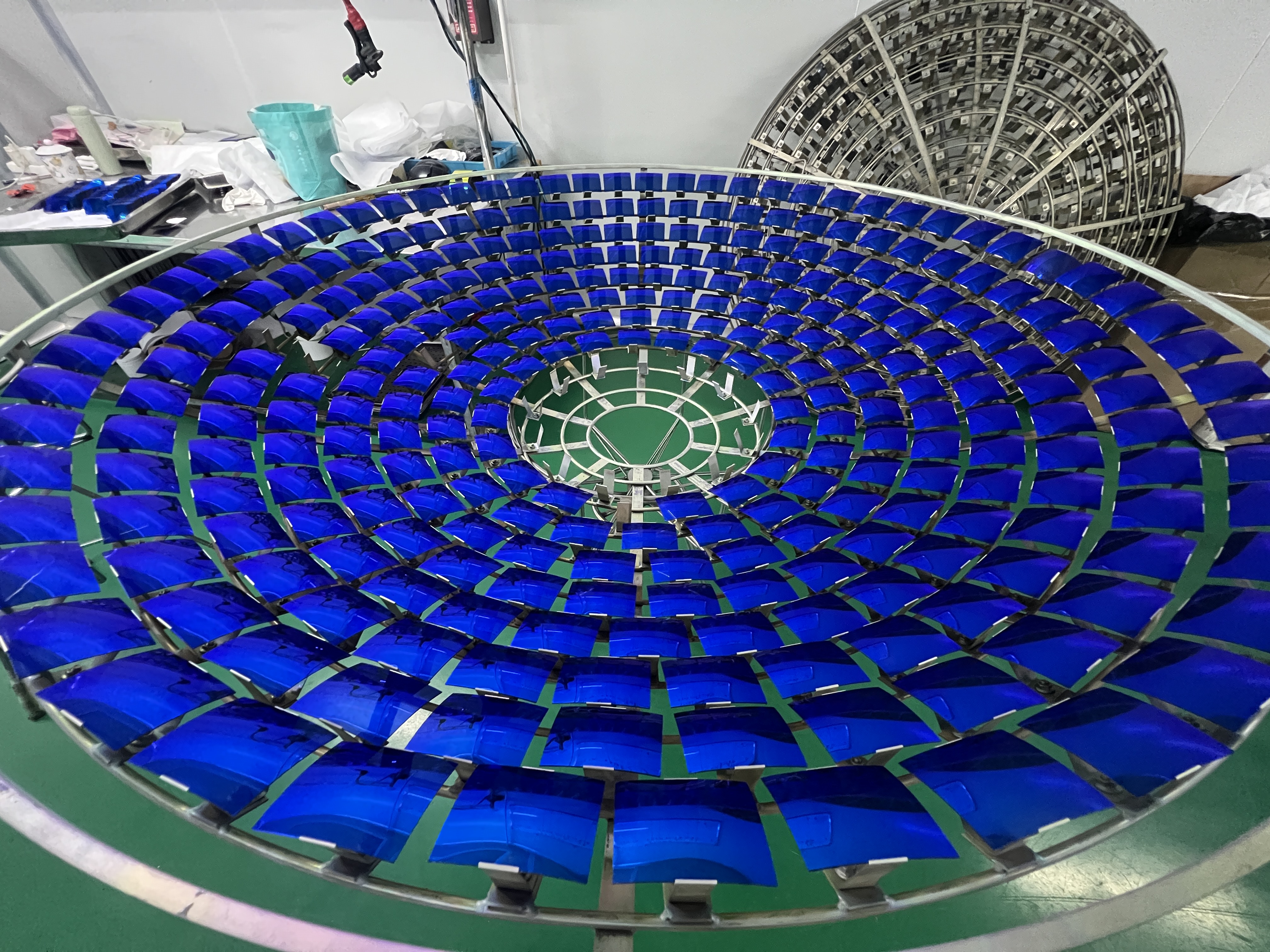

🟣 Glass – Premium Clarity and Scratch Resistance

-

Polarized: ✳ Optional (can be made polarized)

-

Standard Thickness: 1.8mm or 2.0mm

-

Hardness: A (best)

-

Elasticity: D

-

Price Level: A (highest)

-

Typical Uses:

-

Luxury sunglasses

-

High-end designer brands

-

Pros:

-

Superior optical clarity

-

Best scratch resistance on the market

Cons:

-

Heavier

-

Fragile under heavy impact(Hardness can be increasd)

👉 Ideal for luxury brands prioritizing lens clarity and longevity.

⚪ AC/PC (Acrylic/Polycarbonate blend) – Entry-Level and Basic

-

Polarized: Optional (can be made polarized)

-

Hardness: C

-

Elasticity: C

-

Price Level: D (lowest)

-

Typical Uses:

-

Promotional sunglasses

-

Low-cost private label lines

-

Pros:

-

Extremely affordable

-

Lightweight

Cons:

-

Lower optical clarity

-

Weak durability

👉 Best for entry-level sunglasses or temporary collections with tight cost constraints.

🧭 How to Choose the Right Lens for Your Eyewear Brand

Here’s a quick strategy checklist:

✅ 1. Match Lens to Market

-

Sports or outdoor activewear? Choose TAC or Nylon

-

Fashion-focused collection? Go for CR-39

-

Luxury or designer line? Use Glass

✅ 2. Match Function to Style

-

Need polarized lenses? TAC is the most budget-friendly polarized option

-

Require lens drilling or special shapes? Nylon offers great flexibility

-

Prioritize optical clarity & scratch resistance? Glass leads the way

✅ 3. Consider MOQ and Pricing

Some lens types like Glass or AC/PC may have higher MOQs or setup costs. If you're launching your first collection, consider a material like TAC,CR39 or Nylon to balance performance and budget.

✅ 4. Align with Brand Messaging

Use the lens material to enhance your brand story — for example, promoting durability (Nylon), premium clarity (Glass), or performance features (TAC) in your marketing.

💬 Final Thoughts

Lens material is more than a technical decision — it’s a brand-defining choice. By understanding each material’s performance, pricing, and best-use scenarios, you can build eyewear collections that serve both your customers and your brand goals.

At Bright Eyewear, we help global eyewear brands select the perfect lens material for their unique market — whether you’re building your first prototype or scaling your tenth collection.

👉 Get in touch with us to start your next custom eyewear project with expert guidance and trusted manufacturing support.