Custom Eyewear Manufacturing: What Does The Process Look Like

June 06, 2025

Custom eyewear is more than just putting a logo on a frame — it's a blend of engineering, craftsmanship, and branding strategy. If you're launching your own eyewear line or planning to upgrade your collection, understanding the custom manufacturing process will help you make smarter decisions and avoid unnecessary delays or costs.

At Bright Eyewear, we guide our clients from idea to finished product.

Let’s break down what custom eyewear manufacturing typically looks like.

🧠 1. Concept & Design Development

Every successful eyewear project begins with a vision. Whether you have sketches, reference samples, or just a rough idea, we help turn that into a production-ready concept.

You'll work with our design and technical team to finalize:

-

Frame shape and measurements

-

Lens type and color (CR39, TAC, nylon, etc.)

-

Material (acetate, stainless steel, TR90, titanium, etc.)

-

Branding details (logos, temple designs, engraving)

Tip: If you're unsure how to position your brand, we also offer basic brand strategy suggestions, helping you match the design with your market.

🧪 2. Material Selection Based on Function & Style

Each material serves a different purpose:

-

Acetate: Ideal for bold fashion frames with color depth

-

Metal (stainless/titanium): Great for minimalist, sleek designs

-

TR90: Lightweight and perfect for sports or youth markets

-

TAC lenses: Polarized, perfect for cycling and fishing sunglasses

-

CR39 lenses: Stylish and versatile for everyday use

-

Nylon lenses: Strong, flexible, and suitable for drilled or wraparound frames

We’ll help you select materials not just based on price or look, but on the function your customer expects.

🛠️ 3. Prototyping & Sampling

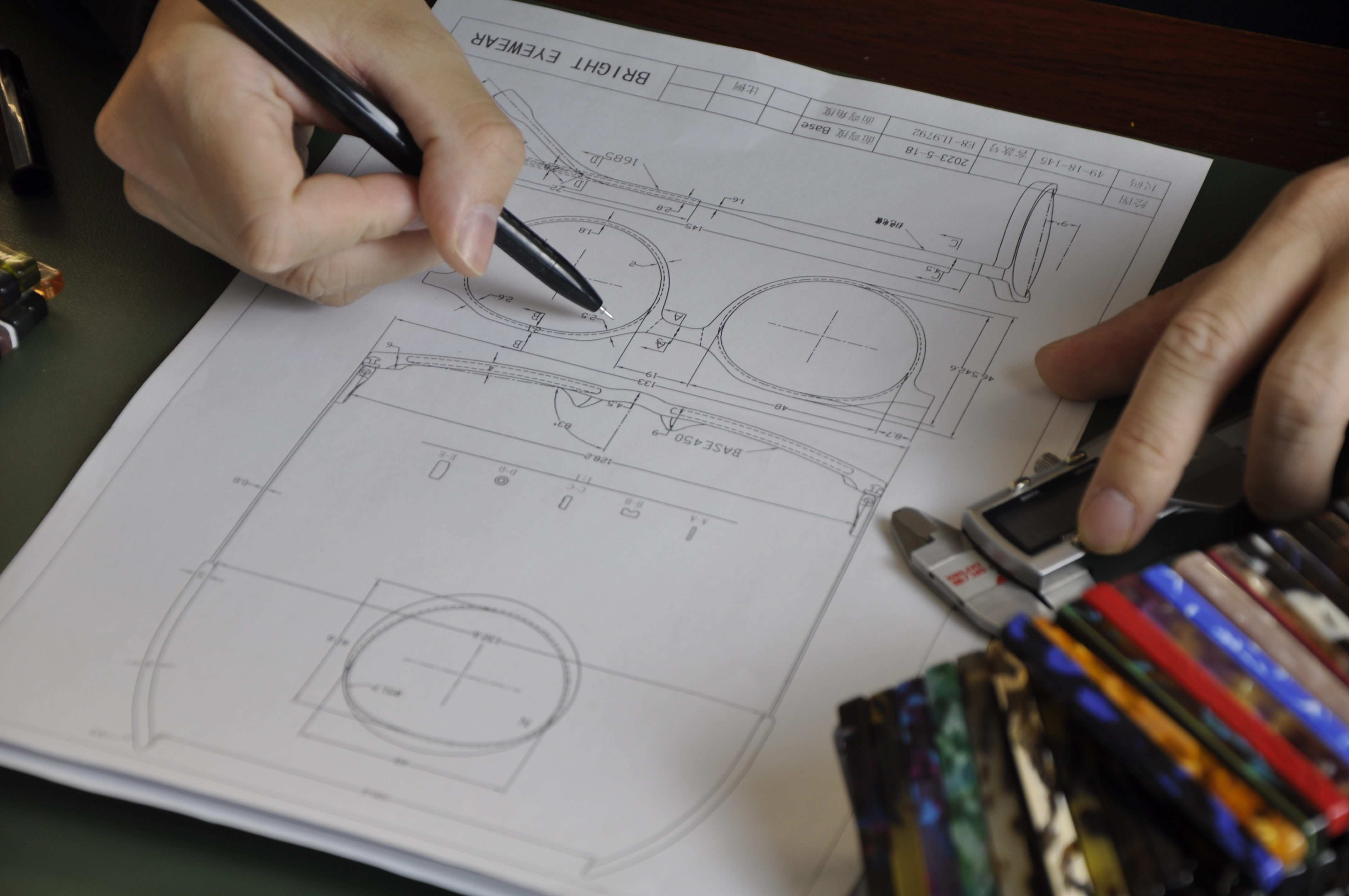

Once the design and materials are set, we move to prototyping. This stage is crucial:

-

Drawings are reviewed and refined

-

A sample frame is produced

-

Adjustments are made based on fit, color, or feel

Some clients go through 1–2 rounds of samples before mass production. We always recommend confirming the sample in person or via video before proceeding.

🎬 Want to see how sampling really works? Watch our video from the “Behind the Frame” series — we show how acetate frames are cut, shaped, and polished into life.

🏭 4. Mass Production

After sample approval, production begins. This involves:

-

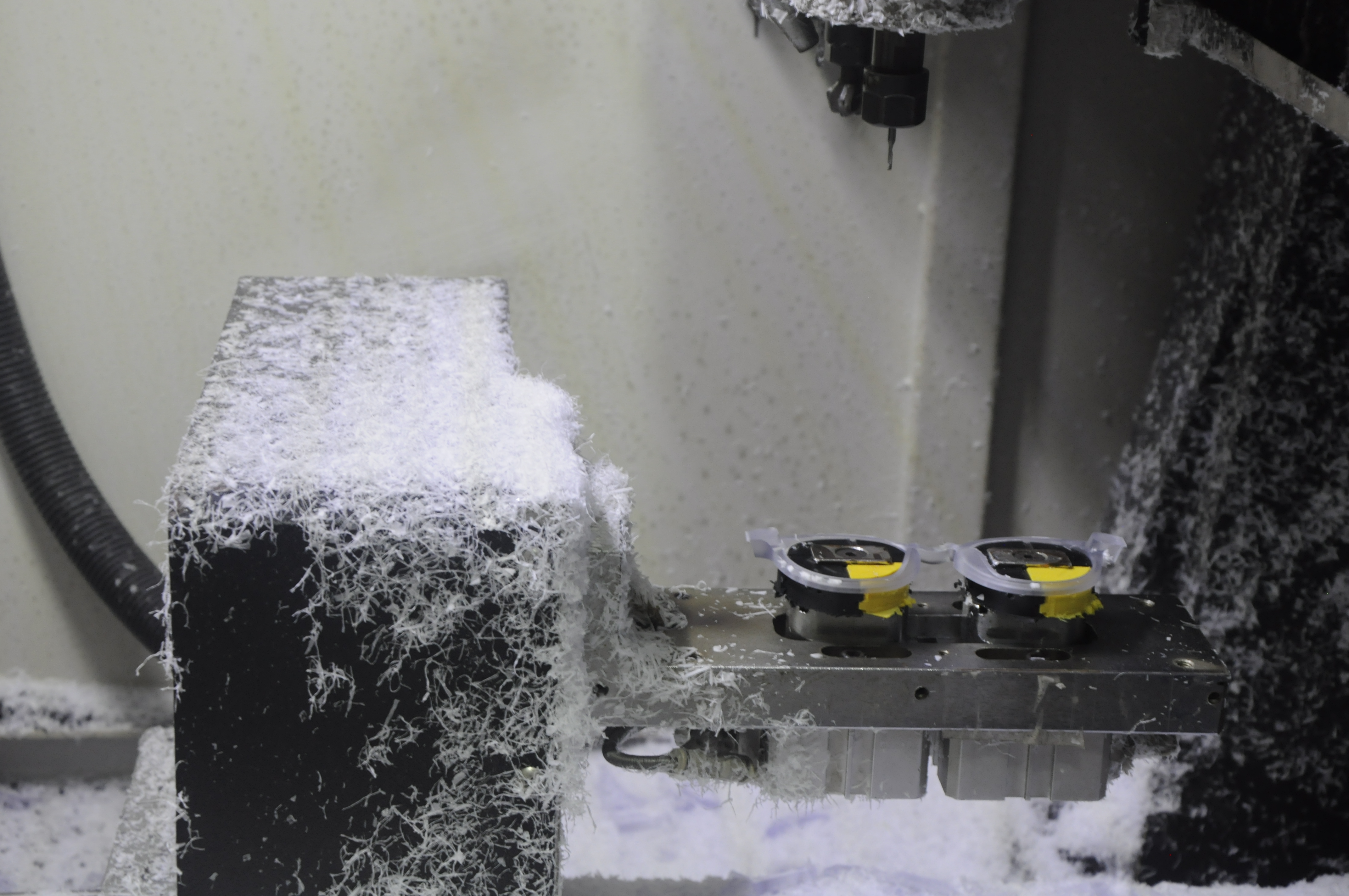

CNC cutting (for acetate or metal)

-

Injection molding (for plastic frames)

-

Hand polishing

-

Painting or plating

-

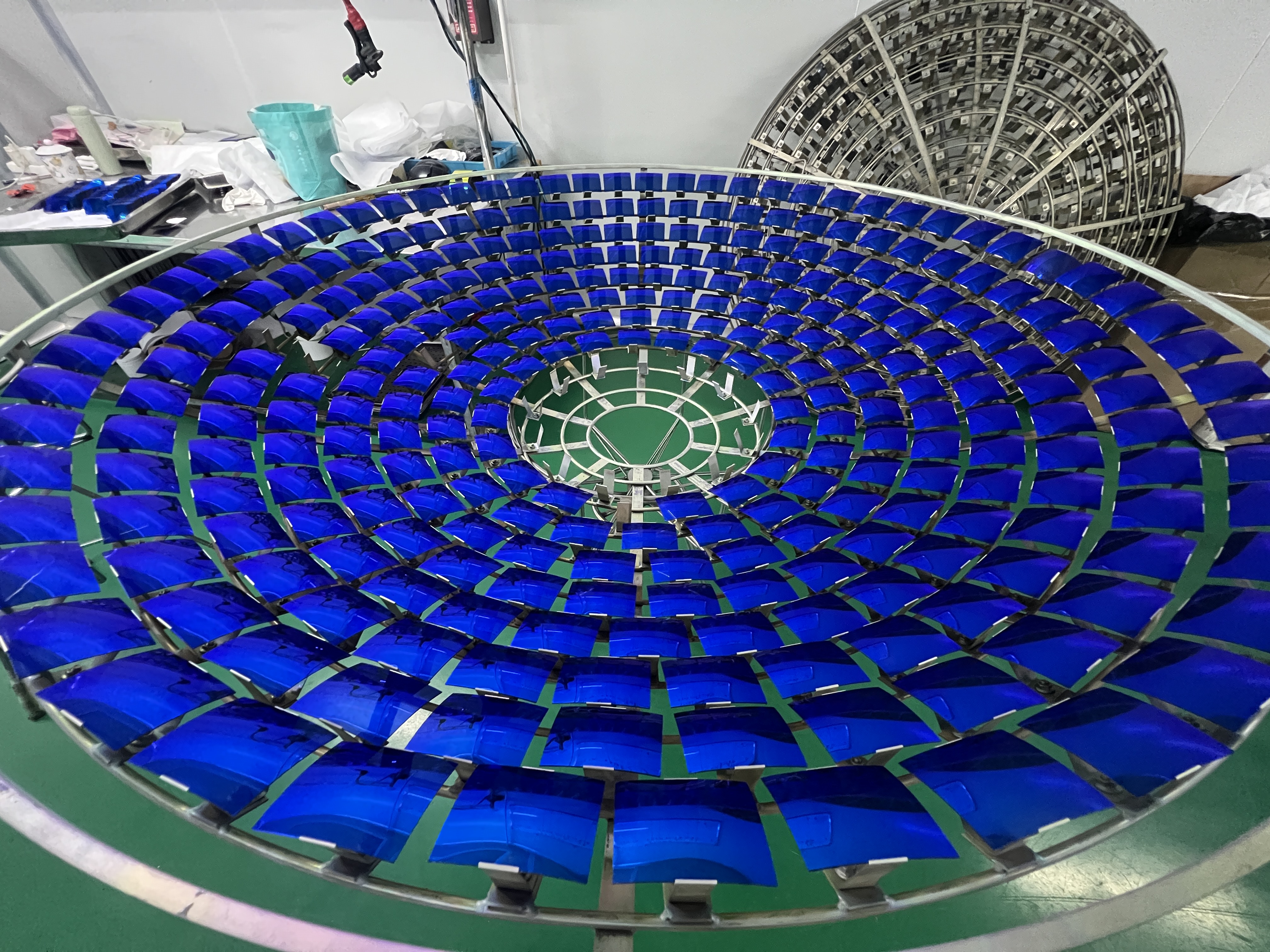

Lens cutting and installation

-

Final QC (quality control)

This is where craftsmanship and precision meet scale — and it's one of the most fascinating parts of eyewear making.

📦 5. Branding, Packaging & Delivery

We also offer support in:

-

Custom packaging (boxes, cloths, cases)

-

Laser engraving or printing of logos

-

Private label compliance for different markets

You can ship via sea, air, or courier — depending on quantity and urgency.

🔁 6. Ongoing Support

Launching a brand isn't a one-time project — it's a process. At Bright Eyewear, we don’t disappear after the first order. We:

-

Offer fast communication (most replies within 24 hrs)

-

Provide production status updates

-

Support reorders, design refreshes, and new concepts

-

Help adjust supply plans based on seasonal trends

Whether you’re launching your first collection or expanding into new categories, we’re here for the long run.

🎥 Step Inside the Factory: Watch Behind the Frame

If you've ever wondered what eyewear production actually looks like, you don't need to imagine anymore.

Our original short video series, Behind the Frame, brings you into our factory floor. In just a few minutes per episode, you'll see:

-

Real technicians crafting frames

-

How metal accessories are cast, pressed, and polished

-

How lenses are cut and installed

-

The real challenges and solutions during production

▶️ Watch Behind the Frame on YouTube

✅ Final Thoughts: Custom Eyewear with Confidence

Custom manufacturing isn't complicated — as long as you have the right partner. At Bright Eyewear, we combine:

-

Decades of experience

-

Flexible production lines (acetate, metal, injection)

-

Full OEM/ODM services

-

In-house designers and engineers

-

Transparent communication and reliable delivery

Let us help you bring your eyewear idea to life — with the care, speed, and quality it deserves.

📩 Contact us now and let's turn your vision into frames that sell.